September 30, 2025

Temperature changes are a fact of life—and a formidable challenge in precision optics. As materials heat up, they expand; as they cool down, they contract. This seemingly simple behavior—thermal expansion—can have a profound impact on imaging performance, especially in systems that combine metals, plastics, and glass, each with its own unique thermal properties.

At the heart of the issue is the coefficient of thermal expansion (CTE), a measure of how much a material changes dimensionally with temperature. Metals and plastics typically expand 10 to 100 times more than optical glass. And because some materials expand differently along different axes (anisotropic behavior), the result can be unpredictable shifts and misalignments inside optical assemblies.

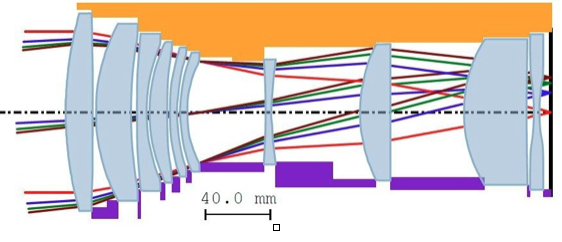

Layout of the 10-element lens with a cross-section of the mounting structure in a seat-based mounting structure (orange, top). The seats are on the right surfaces of the first 6 elements and on the left surfaces of the last four elements. A cross-section of the spacer model schematic is also shown (purple, bottom). Image Credit: OPTICA

The lens designer and opto-mechanical designer will select materials for a spacer-based assembly that will maintain lens performance throughout a wide temperature variation.

Why Thermal Expansion Matters in Imaging

When different materials within an imaging system expand at different rates, it can lead to several performance-degrading motions:

- Roll motion and coupled roll between components

- Decentering of lenses and coupled decenter effects

- Shifts in focus caused by lens displacement or changes in refractive index

Even slight changes in the refractive index—how light bends through a material—can knock a high-precision lens out of optimal alignment. These thermal-induced variations reduce image quality and system reliability, especially in environments with wide temperature swings.

Westech Optical’s Proven Approach to Athermal Design

At Westech Optical, we understand that thermal management is mission-critical in high-performance imaging. That’s why we engineer optical systems that stay focused, aligned, and reliable—no matter the temperature. Our approach combines both passive and active strategies to mitigate the effects of thermal expansion:

1. Smart Material Selection

We carefully pair optical and mechanical materials with complementary thermal behaviors. By minimizing mismatched CTEs, we help ensure that components expand and contract in harmony, maintaining focus and alignment across a broad temperature range.

2. Passive Athermalization

Through innovative lens assembly designs, we create systems that naturally compensate for thermal expansion—without the need for power or external adjustments. This passive strategy is ideal for rugged environments and long-term reliability.

Reliable Imaging in Every Environment

From defense and aerospace to industrial inspection and remote sensing, Westech Optical delivers imaging systems engineered to thrive in real-world environments. Our deep expertise in athermal design, material science, and optical engineering ensures your system maintains clarity, accuracy, and reliability—regardless of the heat, cold, or anything in between.

Have an application that demands thermal resilience?

Let’s talk about how Westech Optical can design a solution that keeps your image sharp, no matter the ambient temperature range.